A wood pallet is a leveled wooden structure that is used for shipping and transport activities. You must have seen one in your big neighborhood stores. They are used to convey heavy finished goods and freight containers, offering them balance and support so they can be hoisted by forklifts, front loaders, jacks, and other jacking machinery.

Pallets allow for effective storage and handling, and even though many pallets are made from wood, you’ll also get to see those made of paper, metals, plastic, or recycled items. Their costs differ depending on the materials from which they are made.

Even though pallets are generally the same, nuanced differences exist between sizes and dimensions for several parts of varying pallet types. In countries like the US, pallets keep to the very renowned standards established by the Grocery Manufacturers’ Association. The GMA is responsible for almost 30% of every wood pallet made in North America, which is fit to carry consumer-end goods.

The GMA standard pallet size in US industries is 48 by 40 inches. They normally weigh 37 lbs and can accommodate about 4600 lbs. The next most regular pallet sizes are 42 by 42 inches and 48 by 48 inches, respectively. Other parts of the world have different wood pallet sizing standards.

Most times, pallets are custom-built to accommodate different load weights or to convey extra-large goods, but in every case, regardless of how broad and or lengthy a pallet turns out, its height hardly changes except when there is a special demand for such.

How Big are Pallets?

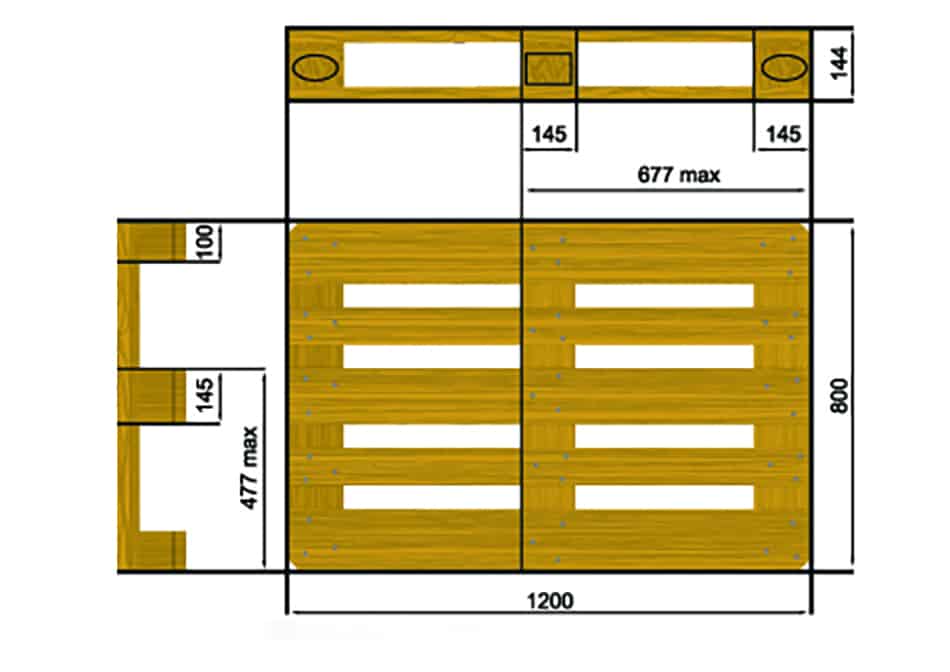

The typical pallet size for the average size of EUR pallets is 800 by 1200 by 144 mm. The dimensions of wooden pallets are calibrated to guarantee that any member of the supply chain in the same region can use the exact type of equipment to preserve, haul, and transport the pallets.

Pallet sizes differ in regions across the World. If you reside in the United States, there is a high probability that the pallet you’ll get will not have a similar size to that in Europe or Australia, for instance. Even though pallet sizes vary among countries in the World, significant progress has been achieved concerning regularity and durability.

The progress was needed as improved global trade required standard pallet sizes that are currently reflected in the International Organization for Standardization Pallet list. Out of all the standard pallet sizes around, the ISO has authorized six pallet dimensions that are currently in use all over the World.

The standard pallet size is crucial as global trade has risen in the last century, and it could bring down freight costs. Freight prices are lower when standard pallets are used as there is the optimum usage of the truck space. When they are used, shippers also collect smaller handling fees.

Standard Pallet Sizes in North America

Shippers importing goods into the United States should note that the GMA pallet recommendation (48 by 40 inches) is the regular pallet size for North American pallets.

They should also be aware that pallet sizes sometimes depend on the type of goods being imported as follows:

- Grocery – 48 by 40 inch – 1219 by 1016 mm

- Telecommunications & Paint – 42 by 42 inch – 1067 by 1067 mm

- Drums – 48 by 48 inch – 1219 by 1219 mm

- Military & Cement – 40 by 48 inch – 1016 by 1219 mm

- Chemicals & Beverage – 48 by 42 inch – 1219 by 1067 mm

- Dairy – 40 by 40 inch – 1016 by 1016 mm

- Automotive – 48 by 45 inch – 1219 by 1143 mm

- Drums & Chemicals – 44 by 44 inch – 1118 by 1118 mm

- Beverage – 36 by 36 inch – 914 by 914 mm

- Beverage, Shingles & Paper – 48 by 36 inch – 1219 by 914 mm

- Military .5 ISO Container – 35 by 45.5 inch – 889 by 1156 mm

- Retail – 48 by 20 inch – 1219 by 508 mm

European Pallet Sizes

The standard European pallet size is known as EUR 1. One distinct feature of this pallet is the EPAL stamp at the left leg side of the pallet, which provides quick identification. On the right leg, you’ll find the EUR stamp.

The European pallet has stamps as well to pinpoint the kind of wood it is made from and when it was designed. The sizes you can find are as follows:

- EUR 1 (1200 × 800 mm or 47.3 × 31.5 inches)

- EUR 2 (1200 × 1000 mm or 47.3 × 39.4 inches)

- EUR 3 (1000 × 1200 mm or 39.4 × 47.3 inches)

Strength of Pallet Wood

The two most popular kinds of wood pallets are stringer pallets and block pallets. A stringer pallet has boards at the corners and center of the pallet that holds a frame. The deck boards rest on this frame. The block pallet, on the other hand, is designed using nine blocks with boards holding them together. These blocks & boards are called the frame, and that is what the deck boards rest on.

The stringer pallet & the block pallet are typically 4-way pallets that allow a forklift to enter from any side. The block pallet is sturdier than the former; however, the stringer pallet is used most times as it is cost-effective.

Wood pallets are loved for being affordable, reliable, easy to handle, and faster to unload and load.

Pallets are unbelievably strong. Many people who use them would be shocked to know that a regular 48-inch by 40-inch wood pallet can carry about 4600 pounds. That’s over two tons.

Pallet Standard Height & Weight Capacity

The Standard pallet is up to 6 and a half inches in height. Each deck board measures 3½ inches and 5/16 inches thick. The carrying capacity of the pallet relies on a lot of factors such as stringer or block and the number of stringers or blocks.

Although, the standard 48 by 40 pallet with 5/8 inch wood thickness can carry about 6400 lbs.

Pallet Specifications

No form of ISO standard is set for foreign pallets, but a lot of countries have pallets that are kind of standard in terms of size.

The discrepancy is in the specifications the pallets have to reach based on the standard of that region. For example, the EUR pallet must attain the requirements under the UIC 435-2.

While the North American Pallet obtained its standards from the GMA as far back as 1906, the International Organization for Standardization supports both kinds of standards as the standard pallet specifications.

Other specs that are commonly shipped overseas are the HT designation. HT means heat-treated and heat-treated pallets are among the most regular specifications.

Pallets are heat-treated to guarantee that wood disease or damage from insects is not conveyed from one region to another, where it can become endemic. In a few countries, the pallet “standardizations” or “requirements” are very strict, and companies that do not follow these standards can experience prolonged delays in customs clearing.

Choosing the Right Wood Pallet Size

There are a few factors you need to consider to make sure you’re making the best choice. Let’s take a look at them.

Factors to consider

Load Capacity

First and foremost, think about the weight of the items you’ll be placing on the pallet. Different pallet sizes have different load capacities, so make sure the pallet you choose can handle the weight of your cargo.

Material type

Consider the type of materials you’ll be transporting or storing on the pallets. Some items, like fragile or sensitive products, may require specific pallet sizes to ensure proper protection during transport.

Storage and transportation requirements

Take into account the storage and transportation requirements for your goods. You’ll need to select pallets that fit the space available in your warehouse or shipping container. Also, consider whether the pallets need to be compatible with certain types of handling equipment, like forklifts or pallet jacks.

Tips for selecting pallet dimensions

- Familiarize yourself with standard pallet sizes in your region, as well as any international standards that may apply to your shipments.

- Consult with your shipping and logistics partners to determine the most efficient pallet dimensions for your specific needs.

- Consider reusability and recyclability when choosing pallet sizes, as this can help reduce waste and lower your environmental impact.

Importance of ISPM 15

ISPM 15 is a set of regulations designed to prevent the spread of pests and diseases through wooden packaging materials, like pallets. To comply with these standards, wood pallets must be treated to eliminate any potential pests, either by heat treatment or fumigation with methyl bromide.

The regulations don’t directly impact the dimensions themselves, but they do require pallets to meet certain criteria, like the type of wood used and the treatments applied. So, when you’re dealing with international shipments, it’s essential to choose pallets that comply with ISPM 15 standards.

Other Things You Should Know about Pallets

Pallets exist in more than one size and also feature various materials and are graded as a result of the wood quality, the solidity of the wood, and if they have been heat-treated or not.

For instance, Grade-A Pallets are the most common types. They are built with hardwoods, and a lot of time and care is committed to their construction. According to estimates, there are more than 4 billion pallets in distribution constantly around the World.

The United States is estimated to have about 1.8 billion in circulation, while the European Union accommodates about 3 billion pallets. They are so in demand that the ones available for supply hardly meet the level of demand.

Pallets offer the dependability companies require to acquire pieces of equipment, components, and goods from one particular area to another. These items are entirely recyclable, thus an added advantage, and can be redesigned to be set back into the supply chain.

Other Types of Pallets

Aside from wood, pallets are made from several kinds of materials, some of which include:

Plastic Pallets

Plastic pallets offer benefits that wood pallets cannot offer. There is a high demand for them, and buyers pay a higher price to acquire them since they are difficult to get. These pallets can be reused, and at times, they are produced from recyclable plastics.

Plastic pallets are the best fit for the food industry as several food-grade options are available. They can be cleaned out when dirty, have a long life span, and can be transported to other countries.

Corrugated Pallets

These types of pallets are very light and can lessen shipping expenses. IKEA now uses corrugated pallets. They are so easy to reproduce as every paper recycler can make them.

Corrugated pallets are safe as well because they have no nails. Their wood boards can’t wither and fall off. The only disadvantage attributed to this pallet type is that they can only be used once. After a single use, they experience a lot of wear and tear that renders them useless.