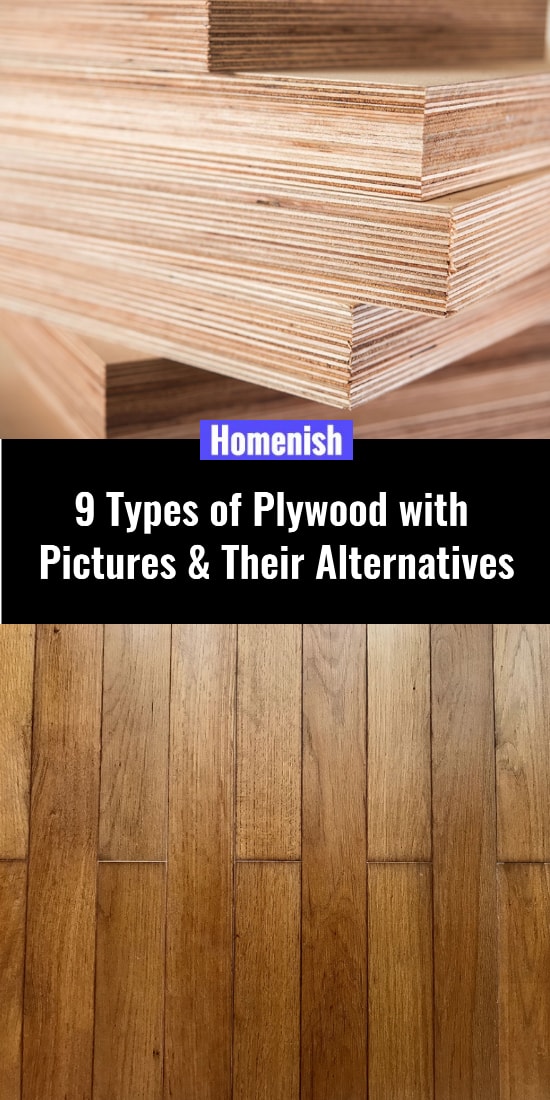

If you have ever used any wood for furniture in your home, you must know this durable & versatile material that looks exactly like hardwood. They are assembled layer by layer of wood into a thick wood chunk and hence are called plywood.

In this article, we’re going to uncover many types of plywood. If you are not interested in plywood for your home projects, we’ll also give you many great alternatives.

What is Plywood?

Plywood is a type of engineered wood that is made by gluing several layers of wood together. It can be made from various types of wood, and each layer can vary in depth. Plywood is a strong and durable type of wood, and much of this strength comes from the way that each layer of wood is assembled.

The grain of each layer will be laid at a different angle so that the grains are running against each other, and this is known as cross-graining. Cross-graining improves the strength of the board in all directions and also makes it less prone to shrinkage, meaning the board can hold its original size and shape well.

It also reduces the likelihood of splitting when it is screwed. Plywood strength is also determined by the type of adhesive that is used to glue each layer together. For indoor projects, a standard glue will suffice, but for plywood that will be used in exterior construction, a weather-resistant glue will make the plywood stronger and more durable.

What is Plywood Used For?

Plywood Strengths

Plywood is available in different strengths, which is determined by the number of layers used to make the board and the depth of each veneer layer. The most common types of ply available are 3 ply, 5 ply, and 7 ply, though you can also find plywood with as many as 13 layers of veneer.

Plywood will always have an odd number of layers, and this is to help balance the board and reduce the chance of warping. The more layers plywood has, the stronger it will be. Thinner plywood, such as 3 ply, tends to be the most aesthetically pleasing, but also the least durable, and so is commonly used in interior construction or for lightweight furniture and shelving.

3 Ply

This type of ply is the most commonly found plywood. As the name implies, this plywood is made from three layers of veneer. It is durable, though not as strong as more heavily layered plywood. The few layers make it quite decorative, making it ideal for many interior projects.

5 Ply

This is another common type of plywood that is ideal for indoor use. It is made from five layers of veneer, and so is very sturdy, though not typically strong enough for use on outdoor projects.

Multi-Ply

This type of plywood can have many layers of veneer, usually with a minimum of seven. It is extremely strong and durable, able to stand up to high winds and storms. For this reason, this type of ply is suitable for exterior use and is commonly used for roofing.

Plywood Types

1. Softwood Ply

Softwood ply is made from various types of softwood, such as fir, pine, cedar, redwood, and spruce. Despite its name, this type of plywood is incredibly strong and is commonly used for roofing, sub-flooring, and exterior frame sheathing. It can also be used in the construction of sheds, summer houses, and children’s playhouses.

In fact, softwood ply is so strong that it can be used in place of concrete on some construction projects. It typically comes in sheet sizes of 4×8 and 5×3. Though it is strong and durable, it isn’t water-resistant and so should not be used on projects where it is subject to the elements.

2. Hardwood Ply

Hardwood ply is known as interior plywood, which is commonly used for indoor cabinetry, interior doors, furniture making, and musical instruments. It is made in 3, 5, or 7 ply and is usually built from inner layers of softwood, with hardwood on the external layers.

Types of hardwood used for this include oak, maple, birch, and walnut. It is also sealed with an extra layer of sealer to make it even more sturdy and resistant to chips and splinters.

3. Aircraft Ply

Aircraft plywood is among the strongest and most durable types of ply available. It is constructed from incredibly thin layers of veneer that make it both sturdy and also flexible.

Aircraft ply will be made from high-quality wood such as birch or mahogany. The finished product will be remarkably strong, as well as being resistant to moisture and heat. This type of plywood is commonly used in building aircraft, boats, and furniture.

4. Exterior Ply

Exterior plywood, as you would expect from the name, is intended for use outdoors. It can be made out of many different types of wood, which is usually a result of the climate it will be used in. Climates that experience more rainfall would be better off with exterior plywood made from oak, as this has natural resistance against damp conditions and is fairly resistant to mildew and mold.

What all exterior ply has in common is the adhesive that is used to hold each layer of veneer together. It will use water-resistant and weather-proof glue to protect it against the elements and maintain its strength over a long period of time.

Exterior ply can be used for various outdoor construction projects, as well as in the making of outdoor furniture. It is strong and has good longevity, though it is not considered to be waterproof.

5. Lumber Core Ply

Lumber core play is usually a 3 ply wood that has been covered on each side with an additional layer of veneer. Typically, the inner layers will be made of three layers of softwood glued together, while the outer veneers will be hardwood.

This type of wood is popular in furniture making, because it is attractive on the outside, and the inside is a texture that is good at grasping screws. This makes it ideal for construction projects that need to be screwed together.

It is worth investing in high-quality lumber core when you will be screwing it together because poor-quality lumber core can often have gaps on the inside, which makes it very difficult when screwing or assembling.

6. Marine Ply

Marine plywood is usually made from Douglas Fir or Western Larch. It is made in the usual way with layered veneer, but the difference is that the glue that binds each layer is a water-resistant adhesive. This ensures that even if the wood gets wet, it will still hold together and retain its shape.

Marine ply must be free of knots in all of its layers and must meet stringent high specifications to be counted as marine wood. This makes marine ply one of the most high-quality types of plywood available. You would be forgiven for thinking that marine ply is water-resistant, given the implications of its name, but in fact, it is susceptible to damage from water, as well as mold, rot, and mildew.

However, the meticulous way it is constructed helps to protect it against these types of issues, and it can be treated with a pressure preservative for added resistance. Marine ply is commonly used to construct items that remain outdoors, such as outdoor furniture and planters.

7. Overlaid Ply

Overlaid ply is the same as traditional plywood, except that it has an outer veneer that has been bonded through pressure and heat, giving it a smooth and finished look. This exterior layer of veneer is for decorative purposes, but it also serves a number of functions.

It makes the ply resistant to abrasion and scratches that might happen during transportation and also means that water droplets or moisture will run right off instead of absorbing into the wood. The smooth veneer also prevents other things from sticking to it.

Overlaid plywood can be purchased in different quality standards, usually either high density or medium density. The type you need will be dependent on the project you are using it for, with the higher-density plywood obviously being stronger and more sturdy.

These types of plywood panels are more costly to buy than regular plywood, but they do offer a good level of protection compared with standard plywood and offer a more finished look.

8. Structural Ply

This is an inexpensive type of plywood that is also known as sheathing plywood. It is widely used in construction for framing, as it is very strong. It is not attractive, and so is used in projects where it will be covered with finished wood. Structural ply gets its strength from its many layers and the strong adhesive used to glue each layer together.

It can be used on both internal and external walls, but it is not weather resistant, and so will need to be protected with a waterproof covering. Structural ply is inexpensive, making it a popular construction material, though, in some instances, it may be worth spending more money for a better-performing wood.

9. Tropical Ply

Tropical plywood is made from layers of tropical woods such as teak, rosewood, and ebony. It was originally manufactured in Asia but is now produced in South America and Africa. It is superior to softwood ply because it is stronger, and it is also favored because it is inexpensive to produce.

Tropical plywood is known for its even layers, high density, and high quality. It is popularly used in construction across the world, though this high demand has led to the overharvesting of many tropical forests in Malaysia and Indonesia.

Ply Alternatives

Though plywood is a versatile material suitable for many construction and carpentry projects, there might be alternatives that are more suitable for your needs. Commonly used types of wood or board that can be used in place of plywood include:

A. Sundeala Board

This is a type of board that is eco-friendly and sustainable because it is made from 100% recycled newspaper and cellulose. This board is able to make useful boards from materials that would otherwise have ended up in landfills.

It is both 100% recycled and also 100% recyclable, which means when it is no longer of use, it can be recycled itself to become useful in another way, preventing wastage.

Despite being made from paper, this is a sturdy type of board that can be used in a similar way to a corkboard. It comes in a wide range of colors and is popularly used in railway modeling and as pinboards and notice boards. Sheets of this wood are typically available in size 4×8.

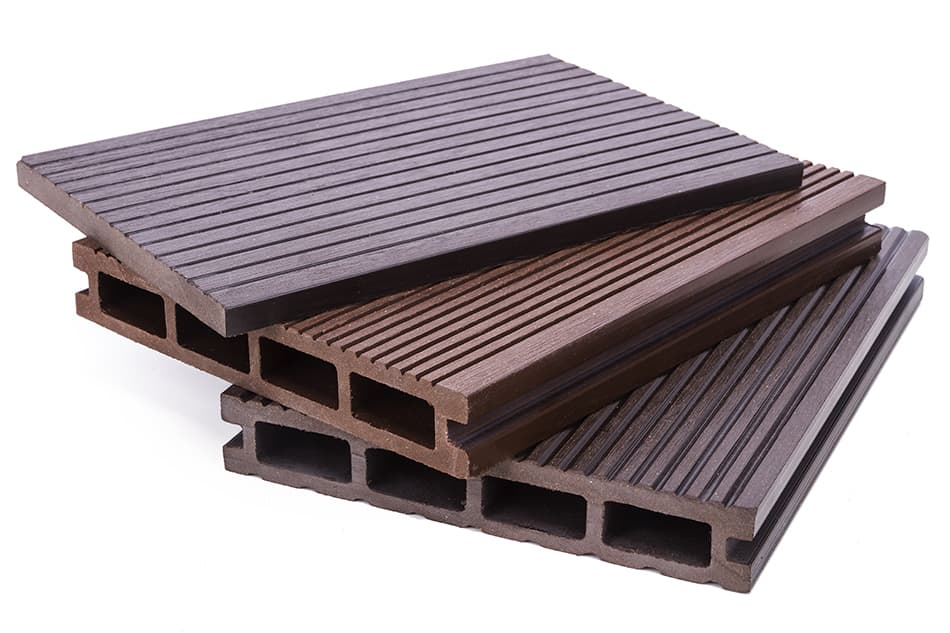

B. Composite Wood

Composite wood is similar to plywood, but it is produced slightly differently. It does have layers, and while the inner layers resemble plywood, the outer layers are made from particle boards covered in hardwood. This type of wood is commonly used in furniture production because it has the benefit of having a strong core while having a decorative exterior.

It gives furniture the look of chunky hardwood, while the inside is actually made from a much less expensive product than if you were to use solid hardwood. This makes furniture pieces look expensive while being considerably cheaper to manufacture.

C. Particleboard

Particleboard is less expensive than plywood but can be used for similar projects. It does not have layers of wood but instead is formed from lots of small wood chippings that have been bonded together to form a solid sheet. Particleboard is heavier than plywood but is much less durable.

It is common for corners of the particleboard to break off, and as it is untreated, it can also swell very easily when it comes into contact with moisture. To ensure greater longevity, particleboards should be sealed in order to prevent water damage. You can buy pre-sealed particleboard, which is commonly known as moisture-resistant particleboard.

This is usually recognizable by its slightly green color, thanks to the green dye that is added to the board to prevent the two from being mistaken for each other. Moisture-resistant particleboard is manufactured in the same way as regular particleboard but is sealed with resin that prevents it from absorbing moisture and swelling or warping.

D. Foamboard

Foamboard is gaining popularity as an alternative to plywood because it is equally strong, though it has rot-resistant qualities. Its core is made from polyurethane foam that has been reinforced with fiberglass.

The outer layers are made from wood veneer, giving the product a finished look. Foamboard is also much lighter than plywood, making it easier to transport.

E. Blockboard

This type of wood has a core that is made from chunky cuts of wood glued together and then surrounded by an attractive wood veneer.

This is a type of wood that is commonly used in furniture making and cabinetry, with a focus on the finish more so than on strength. It can be a good alternative to plywood for shelving and other interior projects, but it is not used for construction or exterior work.

F. MDF

MDF is a type of fiberboard, which stands for medium-density fiberboard. It can be made from softwood or hardwood, or a mixture of the two combined. It is constructed by condensing lots of small wood fibers together with glue, resulting in a strong and thin composite wood. The benefit of this wood is that it is strong and cost-effective.

It is cheaper than plywood, and though it isn’t quite as sturdy, it is stronger than all other low-cost plywood alternatives. As MDF is made from small wood chippings, it is not as attractive as plywood. You are not able to see the grain, which will be a disadvantage for anyone who likes a natural wood look, but it also means that you won’t get knots or any weaker parts in the wood.

It is less tolerant of stress than plywood and may chip or crack when being cut, but when handled correctly, it is very useful. It has a smooth finish that means it can be painted easily, making it ideal for shelf or furniture making if you are happy with a painted finish. The smooth surface of MDF also means it won’t splinter, and it cuts with ease.

G. Hardboard

Hardboard is a different type of fiberboard, which is exceptionally thin and strong. It is also known as HDF, which stands for high-density fiberboard. It is stronger and heavier than MDF, thanks to its exploded wood fibers that have been intensely compressed.

Unlike MDF, hardboard does not have any additional glue added because the organic polymers in the wood are enough to hold it together. This type of board is commonly used as a base for laminate flooring or in kitchen countertops because it is highly resistant to warping or bending.

Like MDF, it comprises lots of small fibers compressed together, so it does not have any visible wood grain. However, hardwood veneer is often fixed to the outside of the hardboard to give it a more visually attractive appeal, or it can be veneered with Formica or vinyl.

This veneered type of hardboard is popularly used for kitchen countertops. Hardboard is seeing a decrease in popularity over recent years as efforts are made to find more sustainable alternatives.