Whether you want to create a hole in wood, metal, masonry, or even bone, you’ll need a type of drill. Drills use pointed bits in various sizes that rotate to tunnel holes into your chosen material. They take various forms, from tiny jewelry drills to huge floor standing drills.

Their level of power and force varies according to their intended use, and they are available with various power sources, including batteries, compressed air, mains power, or manual options.

Most DIY enthusiasts or hobbyists will be familiar with the common corded and cordless drills, which are often used around the home for hanging pictures on the wall or installing wall-mounted shelving.

You might even have drills such as the bench press drill in your garage or workshop if you enjoy carpentry. However, there is a wide range of drills available, many of which you might not even realize existed.

Table of Contents

- Types of Drills

- Corded Drill

- Cordless Drill

- Benchtop Drill Press

- Floor Drill Press

- Impact Drill

- Hammer Drill

- Rotary Hammer Drill

- Earth Auger

- Air Drill

- Brace Drill

- Bow Drill

- Beam Drill

- Core Drill

- Dentist Drill

- Gimlet Drill

- Ratchet Drill

- Radial Drill

- Horizontal Drill Press

- Mini Drill

- Paper Drill

- Push Drill

- Post Drill

- Cranial Drill

- D-Handle Drill

- Hand Drill

- Mill Drill

- Breast Drill

- CNC Drill Press

- Two-Headed Drill

Types of Drills

There are different types of drills and their uses, but they mostly share the same components of a drill, including chuck, grip, motor, clutch collar, speed trigger.

Corded Drill

Corded drills are powered through an electric cable plugged into a mains power outlet, so they have the advantage of being able to be used for as long as the job takes you without the risk of running out of battery in the middle of a project. Corded drills also are typically more powerful than their battery-powered counterparts and can provide more torque, making them useful for drilling in more stubborn materials.

The downside of corded drills is that you will need to be close to a mains power outlet to use one or have an extension cable to hand. These drills are shaped like pistols, making them comfortable to hold in your hand and easy to use. They come in various sizes and have numerous drill bits that can be attached for use on different types of jobs.

Cordless Drill

A cordless drill looks just like a corded drill, but obviously without the cord. These run on power from rechargeable batteries, which makes them portable. Not being tied to a mains power outlet is especially convenient if you need to use your drill outside, for example, to construct a decking area or a fence.

The main issue with cordless drills is that they can only run for as long as the battery has charged, which means your drill could run out of power in the middle of a job, and your project gets put on hold while you wait for the battery to be recharged.

For this reason, it’s handy to have two batteries that fit your cordless drill so that one battery can always be on charge while the other is being used. In this way, if one battery runs out of charge, you won’t have to stop work.

Cordless drills also have a reputation of being slightly less powerful compared to corded drills, but this isn’t always necessarily the case, and some brands have developed technology that allows battery-powered drills to perform as well as corded drills.

Benchtop Drill Press

This drill press will typically be found in a workshop or garage where it is mounted to a tabletop or workbench. However, they are portable and can be taken to different job sites if necessary. On these tools, the drill bit is attached to an overhead component, which means the drill bit faces vertically downwards.

To make drill holes, you will need to place your material on the bench underneath the drill and lower the drill bit down onto it. Benchtop drill presses are versatile because you can attach various bits to them, such as hole saws.

Floor Drill Press

A floor drill press is essentially a large version of a benchtop drill press. This is a floor-standing machine that will usually remain stationary in a workshop due to its large and bulky size. It also goes by the name pillar drill or pedestal drill.

The base has a pillar attached that extends up to the work area. The drill mechanism sits overhead and is pulled down to drill holes through the user’s chosen material that is held onto the work surface. These types of drills are known for being very powerful and sturdy and are a great addition to a workshop if you have space for one.

Impact Drill

An impact drill, also known as an impact driver, is a manual type of drill that can be used to remove nuts and bolts or to tighten up screws. The chunky tool needs to be hit on the back with a hammer and, as a result, will then thrust itself onto a nut while rotating a hexagonal bit. This enables it to effectively loosen nuts and bolts when they have been over-tightened or have become frozen in place due to corrosion.

The impact drill will also ensure screws are properly tightened in instances where a screwdriver does not provide enough torque. This can be done by changing the drill bit to a compatible bit and switching the drill into reverse mode. Some versions of impact drills can be power operated, but these tend to offer fewer functions compared with manual models.

Hammer Drill

This type of drill is also called a ‘percussion drill.’ It is a power tool that is usually powered by mains electricity. Like other drills, the drill bits in a hammer drill rotate at high speed, while the tool provides a series of short hammering pulsing movements to help further power the drill bits through the chosen material.

These types of drills are most commonly used in masonry, where an ordinary drill with a masonry bit may not provide enough force to effectively drill through a very old or very stubborn wall. If you have a lot of drilling to do in masonry, this drill will also help to save fatigue.

Rotary Hammer Drill

A rotary hammer drill is similar to a regular hammer drill, but it has the capability to operate on just a hammer mode with no rotation. It also uses a different mechanism to produce the hammering movements. While a hammer drill is best for drilling in bricks or mortar, a rotary hammer drill is best for drilling in concrete or ceramic tile.

The hammering mechanism effectively works to chisel away at masonry to create a hole. Many different drill bit attachments are available for rotary drill hammers, most of which are intended for larger jobs than hammer drills.

Earth Auger

This type of drill is used for creating holes in the ground. It has a large spiral-shaped blade that rotates to dislodge the earth that stands in its way. These types of drills come in various sizes depending on the job at hand.

They are most often used in construction, where they can help the process of creating foundations in the ground. They are also used on drilling rigs.

Air Drill

Air drills are power tools, but they do not operate via electricity or battery. Instead, they work with compressed air, making them a pneumatic tool. Air drills come in various sizes and also at different angles.

Straight air drills have their bits pointed directly ahead of them, while angled air drills have their drill bit facing downwards at a right angle to the handle of the tool. Types of air drills include jackhammers, which are used to break up the ground.

Brace Drill

A brace drill is a manually operated tool that has a U-shaped handle. The U-shape works like a crank to supply more torque than other manual handheld drills. Brace drills are most commonly used in woodworking and popular in carpentry workshops. They can be used with various different drill bits depending on the desired holes.

Bow Drill

This is an ancient type of drill that is believed to date back as far as the 4th millennium BC. It is designed to start fires by applying friction to create heat that will generate a tiny ember in the wood. The name of this drill refers to the fact that the handle is shaped like a bow. If you’re often camping, it’s a nice tool to have and easy to make a bow drill by yourself.

Beam Drill

This is a large tool that is specially designed to drill holes in beams, as you may have guessed from the name. They work efficiently and precisely at drilling holes in structural beams for supporting buildings, where accuracy is vital to structural integrity.

This tool has a base that rests on the wood and a moveable arm with the drill attached vertically. There is a gap in the base where the user can clearly see the spot to drill.

Core Drill

These tools are required when you need to create large, tunneling holes. They use a solid, cylindrical cutter to powerfully cut holes into walls or other surfaces. This is a large, heavy-duty tool that is most often used in industry and is not typically something you would find in a home workshop. It requires training in order to be used safely, and due to the risk of injury, the tool features a safety clutch.

Dentist Drill

If you’ve ever had problems with your teeth, you’ve likely experienced a dentist’s drill in your mouth. These are small metal drills that have a tiny bit sitting at an angle from the handle. The bit spins at a fast speed, with models generally ranging from 8000 RPM right up to 250,000 RPM.

They emit an intense buzzing sound that might strike fear in the ears of some dental patients while spraying water at the same time as drilling. The water jet serves two purposes; to cool down the drill and prevent it from overheating and also to wash any debris away from the worksite.

Gimlet Drill

A gimlet drill is a handheld manual drill that has a spiral-shaped head that comes to a point. These tools are great for starting holes in woodwork for screws and nails or for creating pilot holes quickly without the need for a power tool. They were designed to drill holes into the wood while ensuring that the wood didn’t split.

One popular version of a gimlet drill is a well-known kitchen tool that is common in most households, and this is the corkscrew. Gimlet drills are best used in softer materials such as softwood or cork, as they aren’t known for their power or strength.

Ratchet Drill

A ratchet drill is so-called because the bit is rotated by a ratchet lever and ratchet wheel. These drills are small, handheld tools with a narrow body that makes them suitable for use in tight or difficult-to-reach spaces. They are designed to drill small holes and are most popular among hobbyists and crafters.

Radial Drill

A radial drill is perfect for drilling a series of holes in a precise straight line. This is because the drill head is fixed to a radial arm, and the drill can move along while maintaining a completely straight line. This makes drilling a number of holes easy and quick, as you won’t have to keep resetting or checking your angle.

This type of tool is great for creating holes in wood that will be assembled into furniture, in that accuracy is vital to ensure assembly goes smoothly. Radial drills are very powerful and are also able to drill through strong metals.

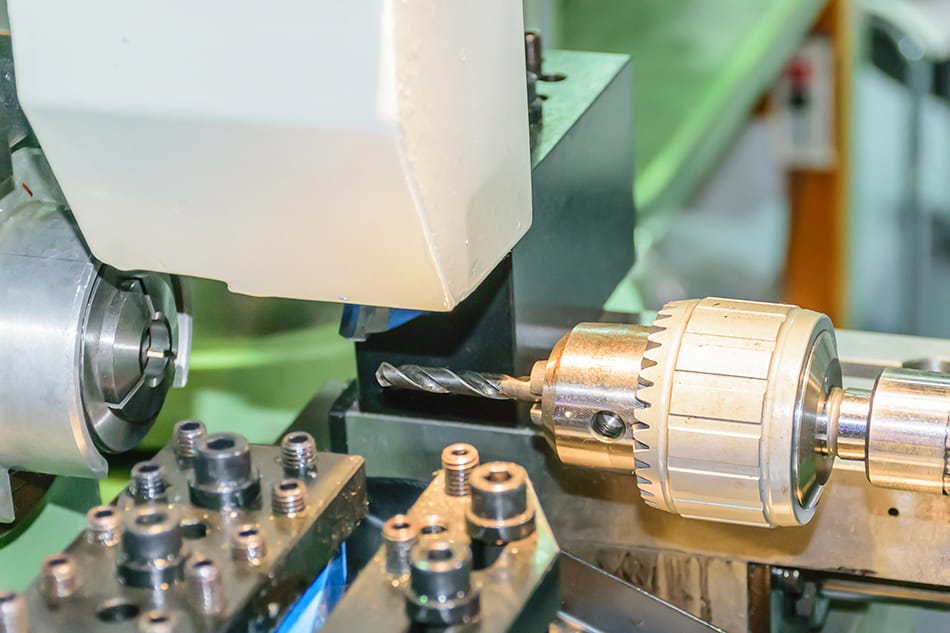

Horizontal Drill Press

This is a heavy-duty tool that stands on the ground and is mounted to the floor for stability. The drill head is fixed at a horizontal angle, and the material will need to be placed in front of it to be drilled. The drill head is operated via a pedal that moves the drill forwards, allowing hands to be holding the material. This tool is useful for working on furniture.

Mini Drill

A mini drill resembles a precision screwdriver and may sometimes be known as a precision drill or a jewelry drill because they are most commonly used on jewelry and watches. These tiny drills are great for tightening or loosening the miniature screws in jewelry, and for complete control and greater accuracy, you should use manual versions of the drill. They are also available in electric and pneumatic versions, which offer more speed and power but less precision.

Paper Drill

A paper drill is exactly that: a drill that creates holes in paper. If you have just a few pieces of paper you need to create holes in, then you would obviously use something much simpler, like a hole punch, but a paper drill is generally used in industrial settings, where notebooks might be manufactured, or in printing shops.

A paper drill looks similar to a bench drill press, with a base that sits on or is mounted to a table or bench. This type of drill can create either one or multiple holes simultaneously in stacks of paper that are up to two inches thick.

Push Drill

A push drill is a very simple yet very effective manual hand tool. It looks similar to your average screwdriver, but where the handle is usually positioned, you will find a shaft containing a special mechanism.

When you push the tool into your chosen material, it causes an internal nut to rotate that subsequently causes the drill bit to turn. This tool is great for making accurate small and plum holes in wood and also for working in small or awkward spaces where larger tools cannot reach.

Post Drill

These drills are named after the fact that they are mounted onto a post. They are an old fashioned piece of machinery that is still in use on some farms or other agricultural settings. These heavy tools are manually powered, and their strength and ability are limited to the manual force applied by the user. With the required amount of pressure, these tools are strong enough to drill through solid metal.

Cranial Drill

This is a surgical tool that is used to create holes or openings in the skull, usually to relieve pressure or allow surgeons access to the brain. These drills have replaced bone saws that were previously used to create openings in the skull.

They feature a special clutch mechanism that automatically stops the drill when it comes into contact with soft tissue, which prevents unintended damage to the brain. These can be manually powered, pneumatic, or electric.

D-Handle Drill

Hand Drill

These drills are also known as ‘eggbeaters’ due to the fact that visually they resemble the old-fashioned whisking tool. These drills are manually powered when the user turns a crank that is connected to a gear.

They are not very powerful and can cause aches or fatigue when operated on for more than a few minutes. However, they are great for making small, precise holes in wood and therefore are very useful in crafting or hobbies such as model-building.

Mill Drill

Breast Drill

This drill is just like a hand drill or eggbeater drill, but with an additional design component that allows the user to apply additional pressure. This is useful if working with a more stubborn material or to save the strength in your arms and hands.

The drill is designed with a curved plate behind the handle, which the user can lean their chest against. It is clear from this design feature why the tool is known as the breast drill. This type of tool is common in workshops and industrial settings.

CNC Drill Press

CNC stands for ‘computer numeric control,’ referring to the fact that it is a commercial type of drill that is set to produce a range of holes in various sizes, patterns, or combinations simultaneously. For speed and precision when drilling mass products, this machine cannot be beaten.

It also serves other functions besides drilling holes, such as turning and milling. It will operate numerous drill bits at once that descend on command, meaning that drill bits do not need to be changed when different diameters are needed. Various designs of CNC drill presses are available, but you can generally expect them to have the drill mechanism overhead, which is lowered down onto the cutting material beneath.

Two-Headed Drill

These drills are relatively new to the market and are targeted at users who want to improve their efficiency or like the thought of having two tools in one.

The two-headed drill takes the shape of a cordless drill and is therefore powered by a battery. It is more likely to suffer from flat batteries as it has double functionality, so having two batteries to ensure you always have one fully charged and ready to go would be beneficial.