What size shed door you need depends on what you want to be able to roll in and out of your shed. Here are the most common door sizes and what they allow clearance for.

The following list of shed doors are all standard sizes, so if you want to change the size of your door, keep in mind that you’ll have to adjust the height or width of the opening accordingly.

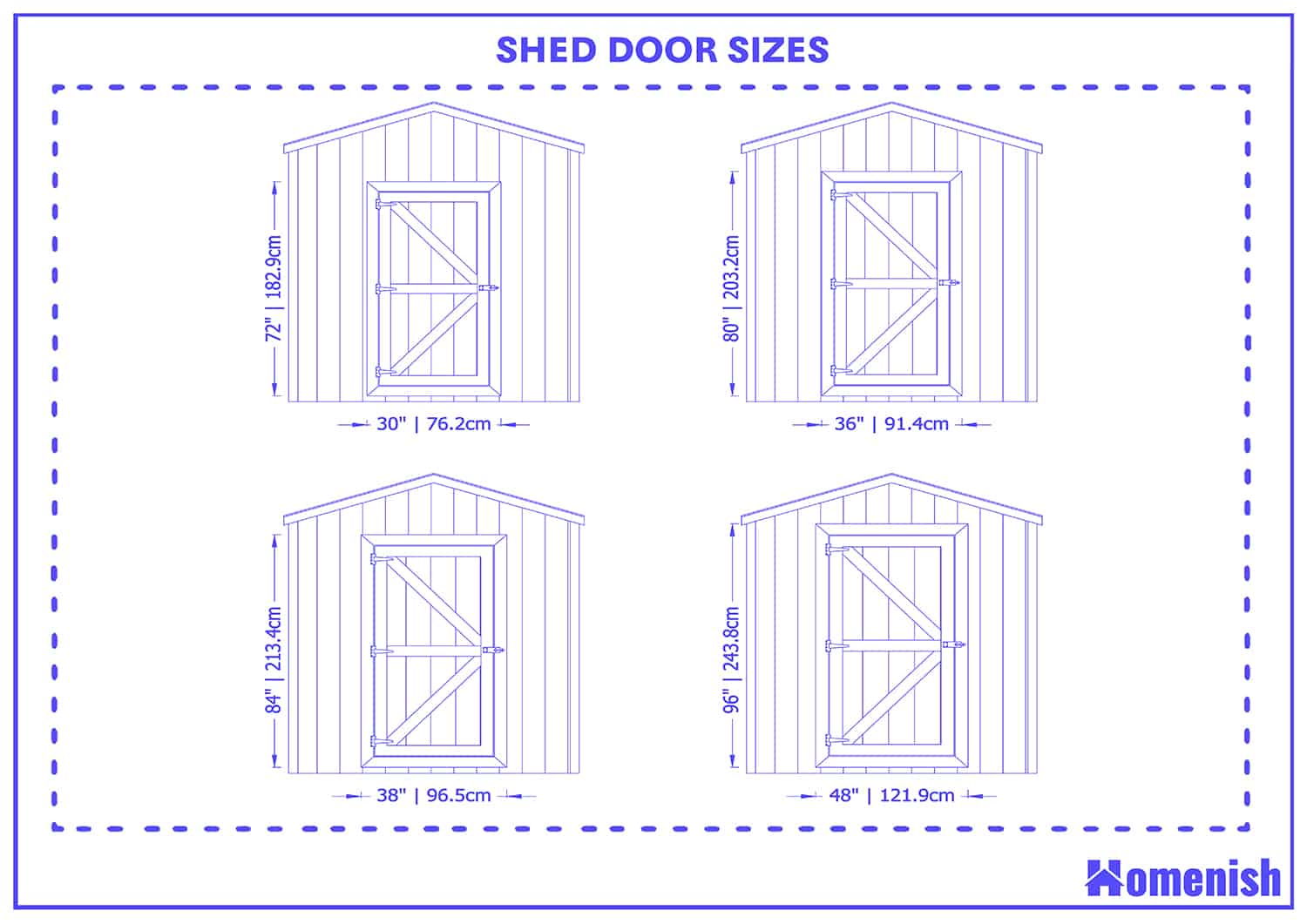

30×72-inch Shed Door Sizes

Using 72-inch-wide siding allows for a 30-inch door with a 2-inch overhang on each side.

If you plan to store a riding lawnmower or ATV in your shed, there are two main considerations: first, the size of the vehicle, and second, how much space you have available.

If it’s an ATV that measures 48 inches wide and 72 inches long, then you’ll need at least a 72″ door width to comfortably fit it inside. Using 72″ wide siding allows for a 30″ door with a 2″ overhang on each side (which makes for a nice square frame).

36×80-inch Shed Door Sizes

The 36-inch door is your best bet if you’re looking to fit a riding lawn mower or ATV into your shed. With a width of 36 inches, it’s wide enough to accommodate the largest vehicles.

The size also makes this style of door easy to build, install, use, maintain and repair. The same goes for replacing if necessary—36-inch doors are easy to find at hardware stores and home improvement retailers alike.

38×84-inch Shed Door Sizes

The 84″ side wall will give you a door that is 38″ wide, and everything will be square.

48×96-inch Shed Door Sizes

A 48″ door is as wide as most two-car garage doors, so it can drive any vehicle in; plus, it’s nice and tall (96″), so you can stand up in it without hitting your head. This size is ideal for those who want to use their shed as a garage or workshop.

How to Install a Shed Door

Installing a shed door is a fairly easy task, but it can be a bit tricky. Without proper knowledge of how to install a shed door, the entire project could turn into something that you regret for months to come. Here are some tips:

Start with the frame and make sure it is level and square. If you have any doubts, it may be best to hire someone who has experience in this area or follow some online tutorials on YouTube so that you can get an idea of what needs to be done before starting your project.

Using 2×6 or 2×8 stock for shed walls will make the shed doors frame exactly square. Use your tape measure to determine the length of each wall stud. Double-check the measurements you have made before you start cutting.

Check that the frame is square to the wall studs and make any adjustments as necessary. If needed, place a carpenter’s square along the bottom edge of one board, then use it as a guide for marking each board for trimming against it.

Clamp together all pieces that need to be nailed together (for example: after attaching two long sides with screws or nails). This will keep everything in place while making sure everything lines up correctly before nailing anything down permanently!

Install the door and make sure it fits properly. You should check every inch of your new shed door before installing it just in case there was anything damaged during shipping or assembly.

Put on hinges after checking the measurements again (in case they changed) due to outside panels fitting snugly against floorboards without gaps between them.

Make sure all screws were tightened correctly; do not forget about those small ones around hinges because if left loose, these could cause problems later when opening/closing doors.

What Material Should You Use for a Shed Door?

When choosing the material for your shed door, there are a few things to consider.

What is the purpose of your shed? If you are using it as storage and will be storing items that are not sensitive to moisture, then plywood or OSB (oriented strand board) may be a good choice.

Plywood is less expensive than OSB but more prone to warping over time. It also tends to sag when exposed to moisture, so if you live in an area with humid summers or experience frequent rainstorms during the winter months, this could cause some issues with your door closing properly.

If you plan on using your shed as a workshop and want something that can withstand all types of weather conditions, T1-11 siding or hardboard may be ideal for you.

Both these materials have been treated with chemicals designed specifically for exterior use and can resist extreme temperatures while still maintaining flexibility when exposed to humidity levels higher than normal (though neither one should be used around pools).

Finally, vinyl siding will offer great durability at an affordable price point—and unlike wood-based alternatives like T1-11 or hardboard boards, which tend only last about 20 years before starting showing signs of wear like splitting out at joints between panels–vinyl siding can last up until 50 years without needing replacement!

However: If aesthetics matter most, then metal would probably be best because some people find they don’t look right on every property; however, they do offer excellent corrosion resistance qualities compared to all other options listed here!

Finally: Fiberglass doors tend not only last long but do not require maintenance aside from occasional cleaning, which means no painting is required, thus saving money over time.