A ratchet is a tool that is used to tighten and fasten tighteners like nuts and bolts. It is used in conjunction with sockets which are sized according to the size of the fastener you are working with. A socket and ratchet are sometimes known as a socket wrench, as technically, a ratchet is a type of wrench.

Ratchets are commonly used in car maintenance and engineering. They are a timesaving tool because they contain a mechanism that allows you to move the ratchet back and forth without repositioning it on the fastener, the same way that you would need to do with a regular wrench.

This is especially helpful when you are working in a small space where you wouldn’t be able to perform a full circle with a wrench, and instead, you can use a ratchet for a much less frustrating and far more seamless experience.

Ratchets are a really useful tool to have on hand, and if you buy a good quality one, it will last you a lifetime. If you are wondering which size of ratchet and socket you will need, here, we will look at the sizes available and what they are best used for.

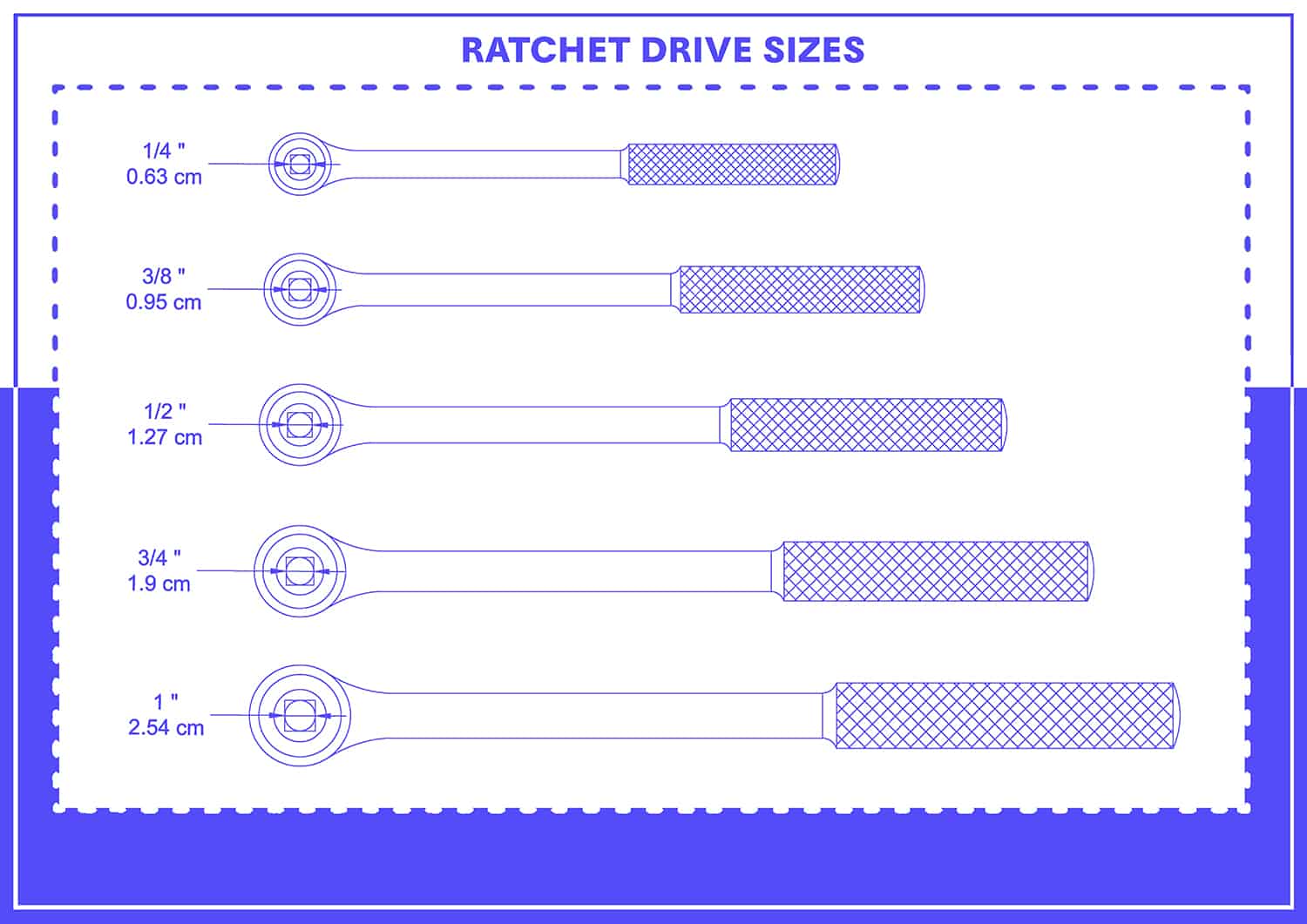

Ratchet Drive Sizes

Ratchets come in several different drive sizes, which will dictate which size of socket they can be used with. These are given in fractional inch measurements, even in countries where the metric system is preferred. They are:

¼ inch

This size of ratchet drive is used for precision work, and it is compatible with smaller socket sizes. You will probably use this size of ratchet drive most when dismantling components on a bench rather than in situ.

⅜ inch

This is the most commonly used size of ratchet drive and, therefore, the size that most people tend to buy if they are only buying one size. It offers a good compromise between the biggest and smallest ratchet sizes, as it is big enough that you can apply a lot of force with it but still small enough that it can fit into quite tight spaces. If you work on cars, then this will by far be the size of ratchet that you work with most frequently.

½ inch

This is the largest type of ratchet drive that you will use on a car and is usually reserved for working on nuts and bolts that are 0.4 inches or 10mm and upwards. You can apply a lot of pressure with this size of ratchet, so it is really useful for unfastening nuts and bolts that are really tight or have become stuck in place. You can use a quarter-inch ratchet drive to undo all of the nuts and bolts on a car.

¾ inch

This is a bigger ratchet that is not commonly used by mechanics and instead is operated by those who work on industrial machinery or tanks and trucks. It will be suitable for use with bigger sockets and bigger nuts and bolts.

1 inch

The one-inch ratchet is the largest ratchet widely available, but like the ¾ inch, it is typically only used by those working on oversized and industrial machinery.

Due to its size, it is very powerful and can be used to exert a lot of force; however, it is also the bulkiest type of ratchet, making it unsuitable for fitting into smaller spaces.

Teeth

Along with the size of a ratchet, you should also pay attention to the number of teeth it has because this will affect how you use it and how well it works for the type of jobs you need it for. Most types of ratchets have geared drives, in which case there will be a wheel inside the ratchet with teeth on, and it is this toothed wheel that determines how big your strokes need to be.

The toothed wheel allows you to rotate the ratchet while tightening the nut or bolt, and if you listen closely, you can hear a clicking noise while using the ratchet. This clicking is the sound of each individual tooth on the wheel passing the ratchet. The more teeth on the wheel, the smaller movement you will need to make to tighten the fastener. This can be especially useful if you are working in a tight space or if you need to operate very quickly.

Ratchets which have a lot of teeth will be more expensive to buy than those with fewer teeth because producing the teeth requires high-quality manufacturing. When buying a ratchet, look for one with a high tooth count as this will typically be a better quality tool, and it will also work faster than those with fewer teeth. The highest tooth count available is 160, but the most widely available has 72 teeth.

Gearless

Gearless models of ratchet are less common, but they are a great option for working in tight spaces because they require smaller movements compared to geared ratchets with teeth. Even models with a very high tooth count will require bigger movements compared to a gearless ratchet, so these are ideal if you have an obstruction in the way that is preventing you from getting a turn on a regular ratchet. Gearless ratchets do not operate via teeth, and as such, they also have a really smooth movement.

Socket Lock & Release

Some ratchets have a lock that keeps the socket in place, preventing it from falling off or getting stuck on a nut or bolt. This can make using the tool a much more seamless and less frustrating process. Ratchets that also have a release button to remove the socket from the ratchet can also really improve the ease of use of this tool.

After a lot of force has been exerted on the ratchet, the socket can sometimes become jammed in place. A small release button that lets the socket slip out will prevent you from having to hammer it out on the occasions when it gets jammed.